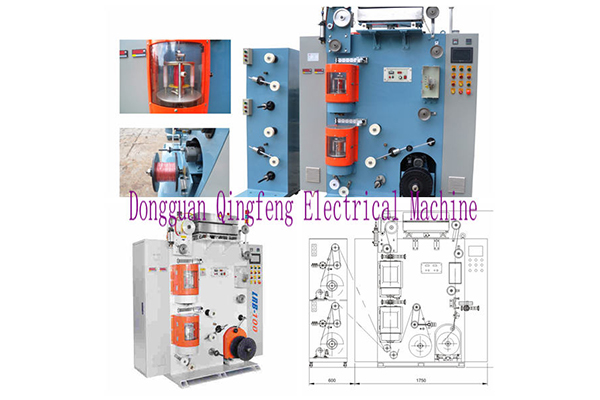

Applied for micro-fine coaxial wire, fine high frequency data wire( such as HDMI, DP, USB), micro-fine high temperature halogen-free electronic wire, micro-fine twisted wire and parallel wire ,with single/double layer continuous central taping, heating wind heating and take-up action accomplished at the same time.

|

Model |

Vertical micro-fine double layer taping machine |

|

Inlet wire(mm) |

AWG32-AWG42 |

|

Drain wire(mm) |

φ0.15-φ0.3 (Optional ) |

|

Tape material |

Small bobbin type of copper foil tape ,aluminum foil tape, cotton paper tape, transparent tape, etc. |

|

Taping (r/min) |

0-2500 |

|

Line speed (m/min) |

1-20m/min |

|

Machine power |

Speed regulation by 1HP servo motor plus servo controller, taping bobbin is linkage with capstan motor. |

|

Taping tension |

Taping tension keep constant from start to end. Don’t use any artificial adjustment. |

|

Capstan type |

Belt half pressing single wheel, pneumatic type regulate belt |

|

Heating Box |

Auto flexible type with Omron temperature controller, the temperature will be controlled within±1°C |

|

Pay off |

Counterweight slider tension type active pay off , inverter regulate speed, with wire broken protection device. |

|

Take up |

Shaft traversing type take up, without damage during wire traversing, which the distance and gap can be set at will. |

|

Drain wire bobbin(mm) |

φ180X185 /φ300X160 (Optional) |

|

Core wire bobbin(mm) |

φ300X160 |

|

Take up bobbin(mm) |

φ300X160 |

Automatic tension trace device, taping tension keep constant from start to end. Don’t use any artificial adjustment.

Setting overlap rate on touched screen, taping point is steady while it’s normal work or accelerating and decelerating.

PLC controlled+ Servo double bobbin taping+ Servo capstan+ High frequency spark tester online test+ Micro power pay-off/take-up tension control+ High performance heating tube which is used in heating agglutinate of outer layer heat shrinkage film.

2.4 Take-up traversing is adopted shaft-traversing type structure, apace can be set arbitrary.

USA

USA CHINA

CHINA